In selective laser sintering, small polymer powder particles are fused using a high-power laser to create solid structures.

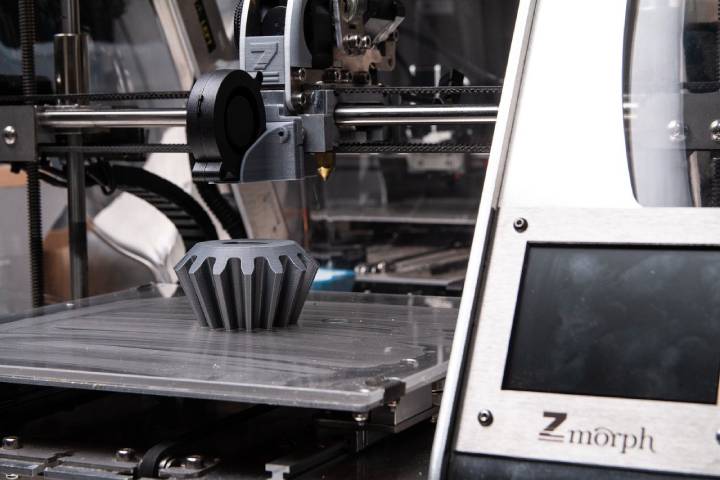

For decades, engineers and manufacturers have used selective laser sintering to make 3D parts. Rapid prototyping to small-batch, bridge, and custom manufacturing is possible with the technology’s low cost and high productivity.

Due to recent advancements in machinery, materials, and software, a wide range of companies can now use SLS printing tools that were previously available only to a select few high-tech industries.

1. How does SLS work?

a. Printing

An interior platform in the build chamber is coated with a thin layer of powder. Lasers can raise the temperature of powder beds to solidify parts. When a 3D model is scanned, the laser heats the powder immediately beneath or at the material’s melting point. It traces the model by preheating the powder to a temperature well below the melting point.

As a result, the metal powder fuses mechanically with the powder to form one solid piece. When printing parts, the unfused powder prevents the need for support structures. In the build chamber, the platform is lowered one layer at a time, typically 50 to 200 microns per layer, and repeats until all parts are finished.

b. Cooling

Building chambers need to be slightly cooled after printing, both inside the enclosure and outside the printer, to ensure their mechanical properties and prevent warping.

c. Post-processing

Excess powder must be cleaned from the parts after they have been removed from the build chamber. Media blasting or media tumbling can be used to process the printed parts further. During printing, the unfused powder acts as a support, so no support structures are required.

Consequently, SLS is ideal for complex geometries, such as negative features, interior features, thin walls, and undercuts. Injection-molded parts have excellent mechanical properties when produced with SLS 3D printing.

2. SLS 3D printing Benefits

A variety of industries benefit from SLS 3D printing. Check them out.

a. Flexibility in design

In addition to multi-piece pieces, SLS printing can produce shapes with internal components and channels and other highly complex geometries. Among its uses are threads, axles, hinges, and tanks.

Geometries such as undercuts, negative drafts, and interior features are also possible. Since the parts are surrounded by unsintered powder during selective laser sintering, it does not require support structures.

b. Materials

Material options for SLS include several types. Polyamides are the most common. They are usually powdered metals. Titanium, gold, silver, and other metals are used in SLS devices.

c. Materials are limited or not needed

With SLS, the build process can be altered, unlike other methods requiring structural support. Since it doesn’t need support materials, it can be further processed to achieve desired properties, such as surface finish and color.

3. SLS 3d printing limitations

SLS 3d printing has some advantages, but it also has limitations:

Inexpensive SLS printers are available. They can cost up to $250,000. The powder can cost $50-60 per kilogram.

SLS produces 3D parts which usually have grainy or rough surfaces.

It takes a long enough time to produce and 12 hours or more for it to cool down.

Tech Trends

Related posts

Leave a Reply Cancel reply

Hot Topics

Categories

- Ads (5)

- Animes (25)

- Artificial Intelligence (AI) (35)

- Augmented Reality (AR) (10)

- Automotive (9)

- Bitcoin (16)

- Blockchain (24)

- Business (244)

- Business Intelligence (3)

- Cloud Computing (23)

- Computer (128)

- Concrete Technology (1)

- Cryptocurrency (10)

- Cybersecurity (42)

- Data Science (9)

- Database (4)

- DevOps (6)

- Digital Marketing (76)

- Digital Workplace (14)

- Ecommerce (1)

- Education (28)

- Electric Vehicle (EV) (1)

- Electronics & Hardware (17)

- Entertainment (42)

- Fabrication (3)

- FAQ's (1)

- Finance & Marketing (47)

- Gadgets (35)

- Games (8)

- Gear (29)

- HTTPS (1)

- Industry (46)

- Information Technology (90)

- Internet (413)

- Internet of Things (IoT) (41)

- Job (25)

- Machine Learning (6)

- Marketing (92)

- Mobile Apps (21)

- Movies (11)

- Natural Language Processing (6)

- News & Trends (109)

- Programming (4)

- Science & Technology (235)

- Security (81)

- SEO (56)

- Services (36)

- Social Media (73)

- Software (99)

- Sports (1)

- Technology (306)

- Telecom (6)

- TikTok (5)

- Tours & Travels (9)

- Uncategorized (11)

- Virtual Reality (VR) (7)

- VoIP (4)

- Web Technology (42)

- Workforce (17)

- Workspace (6)

Stay connected